What is HardTank? It’s a device for fast production of Cold Brew and an original project of the Hard Beans Coffee Roasters from Opole. Only three years have passed since the idea evolved, the first tests were carried out and the prototypes were created, and today Hard Beans can boast a patented device, which in the first year of its launch was among the finalists of the prestigious 12th Annual Sprudgie Awards in the Best New Product category!

“Fast” cold brew – is it possible?

Thinking back a bit further, an almost archetypal image comes up: a group of coffee enthusiasts gathered at the blackboard lists the most important shortcomings of classic coffee maceration along with potential ways of overcoming them, and draws first ideas – in other words: they want to create a device that will solve all the previous problems related to the production of cold brew.

As time goes by, the first ideas are being put into action, such as nitrogen bubbling or percolation, verified by an old school trial and error method. The first prototypes are built using aquarium pumps and plastic buckets. Mistakes only push further actions and the search for new solutions. The first visual designs are created and HardTank begins to take more and more real shapes.

Bubbling is the process of gas flowing in the form of bubbles through a layer of liquid.

Percolation is the process of water flowing through a solid substrate, which causes leaching or precipitation of a substance.

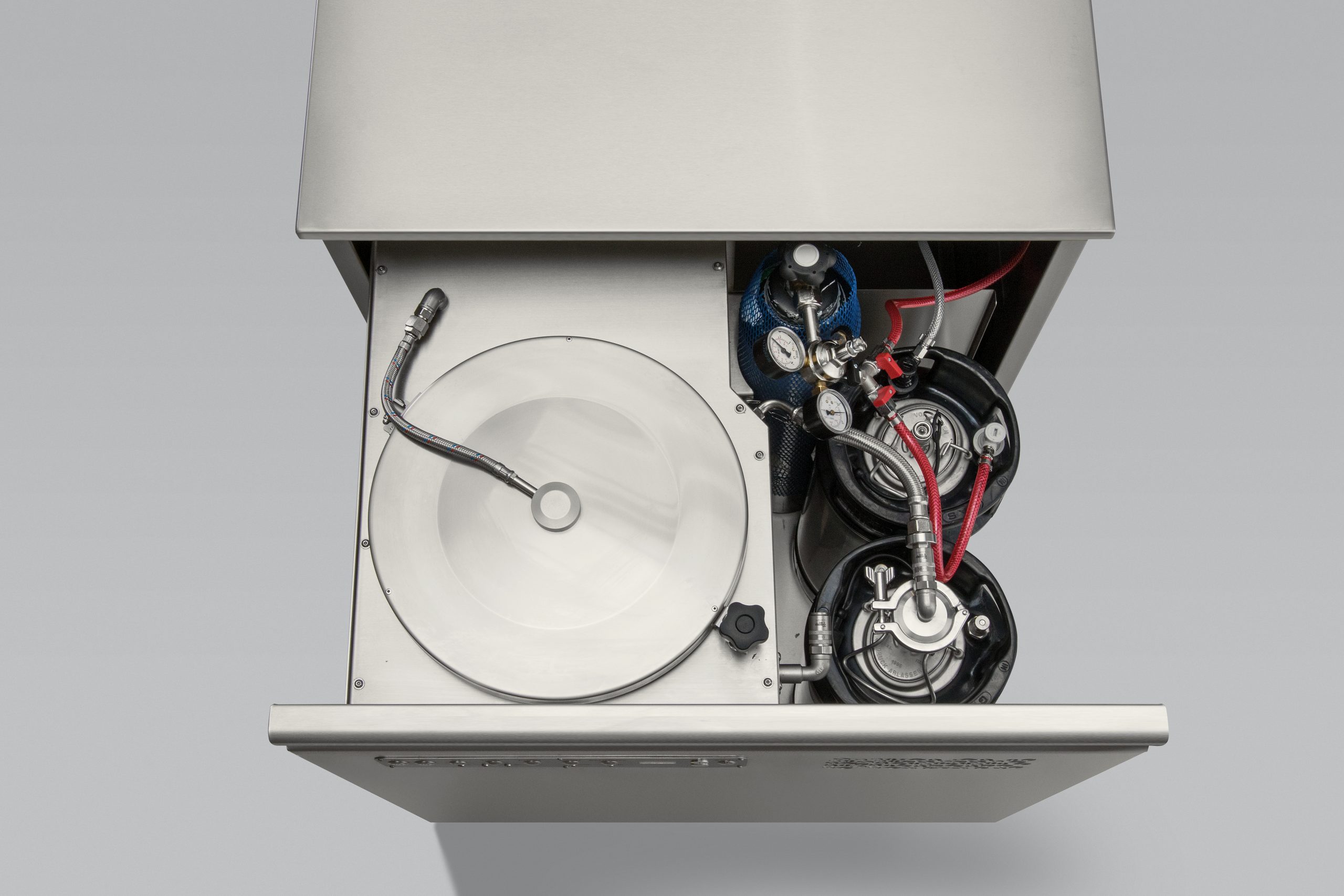

The concept of two versions is implemented: the basic production version and the version which enables simultaneous production and serving of Cold Brew and Nitro Cold Brew. The design engineers go to great lengths to fit not only a keg, but also a nitrogen bottle and a cooler within the established framework. Time flies relentlessly as HardTank gets closer to its launch day. It is scheduled to see the light of day during the international World of Coffee Trade Show in Berlin. Enthusiastic reception aside, the designers do not sit back and immediately start implementing new functions.

First tests… and experiments

In the meantime, tests began on the first serial pieces. The full production capacity could be checked thanks to the collaboration between Hard Beans Coffee Roasters and Browar Szpunt, a craft brewery. The launch of two coffee-based beers, Nitro Beans and Imperial Beans, required 670 and 170 liters of nitrogen-saturated Cold Brew, respectively. In order to maintain the coffee character of the stout, without it being diluted, a double concentration of Cold Brew was prepared. To obtain the desired effect, it was necessary to set a row of 5 HardTanks and operate them all at the same time. Only in this way was it possible to prepare such an amount of Cold Brew in such a short time, because the supply of fresh macerate played a key role.

In addition to checking the full production capabilities of the HardTank, various experiments were carried out. The Hard Beans team would not be themselves if they had not jumped into the deep water right away. Cascara Geisha from Finca Deborah in Panama came first. Next, they macerated teas: green, black, fruit, herbs and even hibiscus flowers, which, of all the experiments, was most enthusiastically received. In a burst of euphoria, an even bolder idea was born: what if the coffee in HardTank was poured with good alcohol? All kinds of alcohol were tried out: potato vodka, grain vodka, rum, whiskey, and the effect, in the form of coffee liqueurs, exceeded all expectations.

How does it work and why has it been successful?

The success would be unattainable without the support of the National Center for Research and Development and local research units. Close cooperation with the Biotechnology Department of the University of Opole resulted in a number of microbiological tests, including on the presence of bacteria, molds, yeasts or microbes in Cold Brew, which allowed to implement the basic design assumptions and deal with the most common pitfall faced when preparing traditional Cold Brew – that of hygiene. In turn, the contribution of Opole University of Technology and subsequent research and tests, both on materials and technology, contributed to the optimization of the maceration process and the parameters of the HardTank itself.

As a result, the extraction time was significantly reduced. While the production of cold brew with the traditional method takes just over 24 hours – including filtration and cleaning of the equipment – in HardTank the entire process can be completed in just an hour, and in the case of teas in less than 15 minutes. Just pour ground coffee into the basket, place the basket in the tank, close the tank, insert the drawer, start the desired program on the control panel and… that’s it! After a set time, the device will pour the cold brew through the filter system directly into the keg. All that remains is to empty the basket, because the dedicated program will thoroughly clean the tank and all pipes by itself.

Here’s a quick visualization of how it works, step by step:

Interested in the machine? For more information see: www.b2b.coffeedesk.com.