Although the world of specialty coffee is still dominated by three main types of coffee processing, there have been more and more interesting experiments in this field in recent years. The effects are getting better and better, resulting in roasteries offering specialty coffee that is even more special. In 2021 both coffee professionals and coffee enthusiasts are expected to know more about processing methods than a brief mention of either “washed, natural or pulped natural”. So, what is modern processing all about?

Why do we process coffee?

Why do we need coffee processing at all? Each coffee cherry consists of layers. These include: outer skin, pulp, pectin layer, parchment, and silverskin – the last layer surrounding two beans locked inside. The goal of processing is to get rid of these layers and get to the essence of the product, and then to dry the bean to the optimal level. However, many desirable, interesting flavors come from the fruit, juice or pulp, and not from the seed itself. And we want them to get into the bean! That is why processing is such a crucial and demanding task.

There are many ways to get rid of layers. Each method will significantly impact the final taste of the brew that you pour into your favorite mug.

The ‘old’ and traditional methods of coffee processing

Natural

The oldest processing method. The fruit is dried first and the layers are removed in step two. It comes from countries with limited access to water, such as Ethiopia and Yemen. The technique works best in conditions of strong sunlight and relatively high temperatures. The harvested fruit is dried entirely in the sun, making sure it’s evenly spread and regularly turned. Once the moisture level is accurate, when the fruit looks more like a raisin than a fresh cherry, the bean is separated from other layers.

In the flavor profile of correctly processed naturals, you often get:

- high sweetness

- characteristics of highly ripe fruits: strawberries, blueberries, tropical fruits

- non-dominant acidity

- rich body

Washed

This is the dominant coffee processing method. Beans processed in this way are more acidic than naturals. They are perceived as cleaner, more transparent and complex in taste, with lighter body. Wet processing is popular in African countries and Latin America.

The ripe fruits are passed through the depulper, which separates the seed from the flesh, but a lot of the pulp still remains on the surface of the seed. For this reason, the seeds are thrown into water, where the remaining layer falls off the bean. The beans also undergo fermentation. Depending on the technique, washing station, climate and many other factors, such a process takes from several hours to even several days. The coffee is then taken out of the water and dried in the sun or in the shade.

Pulped natural / Honey

These two processing methods are very similar to each other. They fall somewhere in between the methods mentioned earlier. In the harvested cherries the seed is separated from the pulp, but it is not soaked in water. The beans are dried, covered with a certain layer of pulp. The amount of the initial amount of pulp stuck to the bean will have a significant impact on the taste of the coffee, but also on the naming of the process. And so, ordered from the smallest content of the adhesive substance up, you get: white honey, yellow honey, orange honey, red honey and black honey. Fermentation time is a variable that farmers like to manipulate in this case as well.

The names pulped natural and honey are used interchangeably by some people. Others distinguish these processes by the basic mucilage layer left on the seed in pulped natural and some extra pulp in honey.

In the flavor profile there is:

- no deep, mature fruitiness characteristic of naturals

- clear sweetness

- acidity not as dominant as in washed coffees, but often marked more clearly than in naturals

Here are three, recently popular, modern methods of coffee processing

Anaerobic fermentation

Increasingly popular in Central American countries such as Costa Rica and Honduras. The cherries are thrown into the de-pulper. The separated seeds are then placed in airtight fermentation tanks. The pulp and parts of the fruit that were obtained separately from de-pulping are added. The tank is then sealed and oxygen is sucked out. The process takes approximately twenty hours. During this time, the pressure in the tank increases due to the carbon dioxide produced during the fermentation. Its level as well as sugar level, temperature and pH are meticulously measured. The reactions must be stopped before alcohol is produced from the progressive fermentation.

The magic trick in this processing method is to “push” substances from the juice and pulp into the beans using the high pressure in the tank.

Characteristics in the cup:

- creamy, silky texture

- complex, interesting, “wild” acidity

- notes of cinnamon and flowers

Lactic process (processing with lactic acid bacteria)

Yes, that sounds complicated. It is the flagship and continuously developed process of the La Palma y El Tucan plantation in Colombia. Processing also takes place under anaerobic conditions, but the fermentation environment takes place with lactic acid bacteria cultures. The bacteria feed on the sugar contained in the pulp, which produces lactic acid. PH measurement is especially important in this case. At the right moment, fermentation is stopped and the beans are soaked in clean water to stop the growth of bacteria. The last step is drying, as with any other processing method.

Characteristics:

- unusual, “wild”, distinct fruity notes

- milky notes

- complex, pronounced acidity

- complex aroma and flavor

Carbonic maceration

Many times, in trainings, workshops or discussions about coffee, analogies are drawn between coffee and wine. Similar sensory concepts and descriptors, differences between botanical varieties or the essence of terroir are in fact common features of the two products. But you can go one step further. This type of processing stems from the method of processing grapes, combined with the movement of natural wines. In the context of coffee, it was first described by Sasa Sestic at the 2015 World Barista Championship.

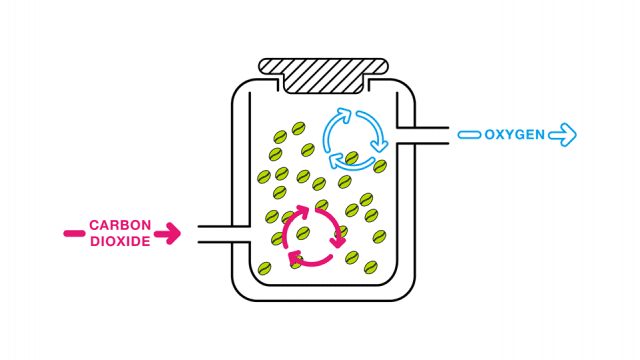

It is also an anaerobic process. The whole ripe fruit is placed in an airtight tank. The tank is closed, then carbon dioxide is forced into it, which, as a gas heavier and denser than oxygen, “pushes” oxygen out through a special valve. Characteristic for this process is the migration of substances called tannins and anthocyanins into the bean. Many chemical reactions take place there, the products of which are responsible for the original, unusual taste of the coffee processed in this way.

The next step is proper processing! The beans processed in this way can be used in both dry and wet processes. Depending on the final method, techniques and terroir, interesting taste characteristics are obtained, such as: ripe strawberries, cherries and raspberries, notes of banana or bubble gum.

Look for interesting coffee processing types on the packages! Atypically processed coffee beans are available in the roaster’s offers more and more often. If you are lucky, you can find such characteristics in coffee that even the biggest coffee freak would not expect!